An energy analysis will return information to optimize the efficiency of a piping/tank system. Being hot OR cold, an energy analysis will show how much energy is being lost. Our certified Energy Appraisers can design the proper insulation system that will quickly pay you back.

THE PAYBACK ON A STEAM SYSTEM IS TYPICALLY 3-6 MONTHS!

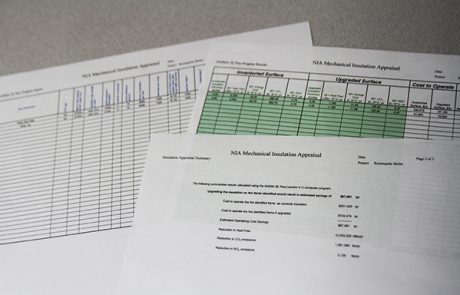

After the information is gathered, a detailed proposal is created containing potential cost savings with the proper insulation type/thickness.

A steam system will return the most savings as the system requires a large amount of energy because it involves the boiling of water. Ambient air is usually about 75 degrees Fahrenheit which is much cooler than steam. Insulation will create a barrier between the two temperatures resulting in less energy to keep the steam at operating temperature.

It is also important to insulate cold systems due to the ambient air around the pipe containing water in a gaseous form. When the humid air contacts the cold pipe, condensation will develop which will then lead to ice forming on the pipe/vessel. The additional weight of the ice can cause damage to the over-loaded system and can lead to corrosion of the metal.

Insulation with a vapor barrier will keep the humid air from coming in contact with the cold pipe and will eliminate condensation and keep ice from forming. The potential cost savings of a cold system is still large but will not show as quickly as the potential cost savings of a steam system. The payback for insulating a cold system is typically over a year.

Jergens Insulation is energy appraised certified by the National Insulation Association. We have the tools to present you with accurate calculations and the knowledge to discuss your potential savings.

KYLE ADAMS

CERTIFIED ENERGY APPRAISER

269.496.7030